During the initial brunt of the COVID-19 pandemic, everyone found their own means of staying sane. Some picked up knitting, others started gardens. Me? I built a laser cutter (and took up beekeeping).

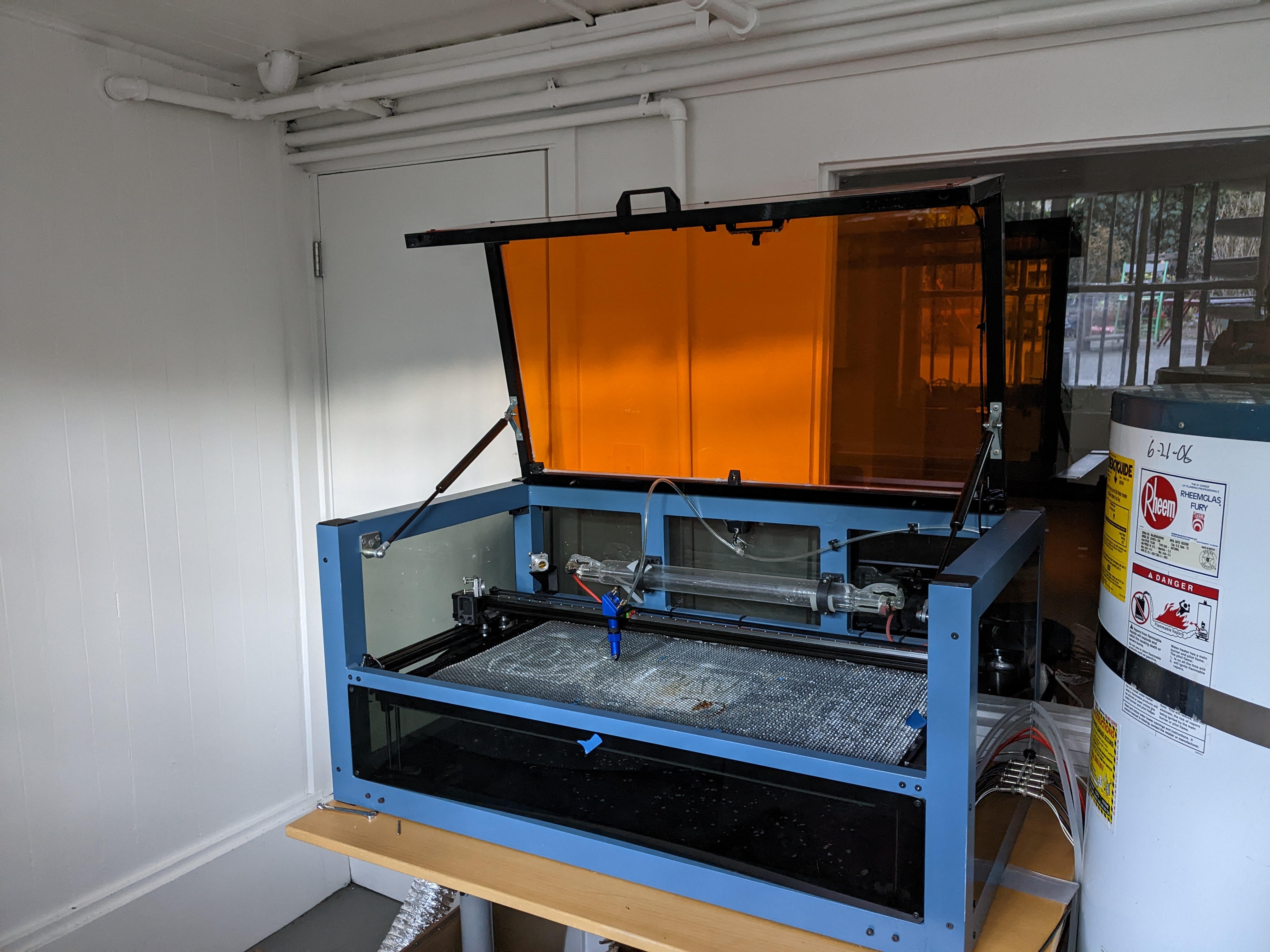

~34”x18” cutting area Adjustable height z table (motorized) ~40-60W Laser Tube

Right before the pandemic, I had picked up a cheap craigslist special K40 laser cutter. I’m not a fan of K40 lasers (safety concerns, tiny cut area, bad optics, and a whole lot more), but the deal was good enough that I jumped on it solely to obtain the laser tube and power supply. Given copious amounts of free time during the pandemic, I set out to finally use the tube.

The laser runs it’s electronics external from the main laser chasis (conveniently not pictured, because they’re still a mess… I’m working on it). The interfacing for this can be seen on the right sidepanel of the laser, an array of GX series aviation connectors (as well as plumbing passthroughs). This was done to maximize the cut area of the laser, while keeping the electronics isolated from nasty laser cutting vapors. The laser runs on a Cohesion3D LaserBoard and LightBurn Camera, and the original K40 laser supply. I use LightBurn as the host software.

The lid and frame of the laser is composed of welded aluminum box tubing. The X motion system is a standard linear rail and belt setup, whereas the Y motion system is a duel “belt and pinion” setup on v-slot rail. The Z motion system (movable laser table) is… more complicated (and needs to be eventually redone). The Z Table sits on threaded rods at the four corners, of which each threaded rod is connected to a common belt. A single stepper drives this belt to (slowly) move the table up and down.

I want to eventually re-do the Z motion system as the current mechanism is not fixed in X and Y. That is, an object placed on the motion system does not maintain it’s X/Y position at varying Z heights. It’s close, but not perfect. This isn’t an issue for the intended use of the table (focusing the laser). However as I’ve learned more about laser cutters, I’ve been desiring a more X/Y repeatable Z table. This would allow me to play with features like focus tracking, or continuous focus adjustment to minimize laser kerf.

A redesigned z table would likely ride on a linear rail (or v-slot).